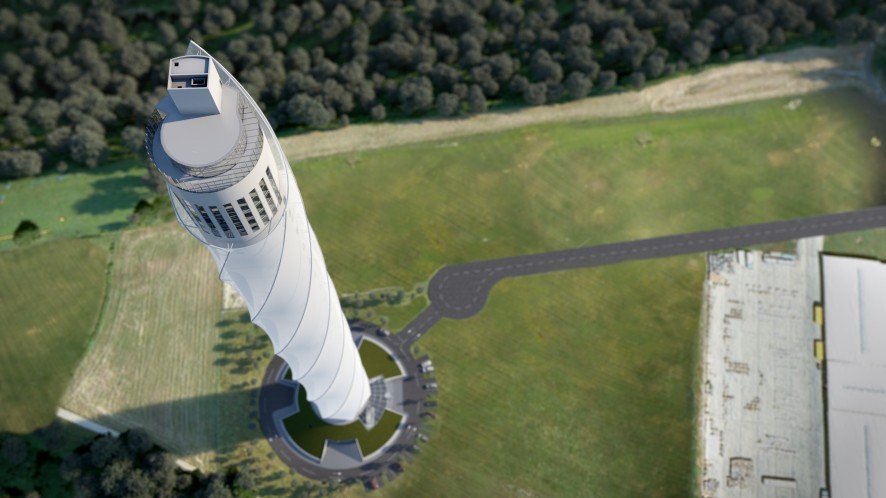

thyssenkrupp’s test tower shows how it should be done: Construction work remains fully on schedule

Construction of the thyssenkrupp test tower in Rottweil is progressing on schedule. At a press conference on the status of the project, thyssenkrupp Elevator CEO Andreas Schierenbeck reported on the development of the extraordinary structure: “Thanks to the dedicated teamwork of everyone involved, the tower has been erected fully in schedule. In the future, the test tower in Rottweil will play a key role in the implementation of thyssenkrupp Elevator’s global innovation strategy, which is critical for the success of the company.”

Interior work at the test tower is currently in full swing: The fire-fighting service elevator was installed at the beginning of the year and is now transporting site workers to the upper floors at around 4 meters per second. The panoramic elevator was installed last week and is clearly visible through its glass shaft; in the future, it will enable visitors to access Germany’s highest viewing platform at a height of 232 meters. At the company’s plant in Neuhausen, one of the largest drive units is ready and waiting to be installed; it will soon move the quickest elevator in the test tower through the shaft at up to 18 meters per second. A similar drive unit is already in use at One World Trade Center in New York and at the Shanghai World Financial Center.

At the end of January, a huge pendulum held by electromagnetic linear motors was installed inside the tower – at a height of 193 meters – by GERB Schwingungsisolierungen GmbH. While this technology is already featured in high-rises in New York, Shanghai, and Dubai, this particular device is the first in the world to combine active and passive movement. Thanks to the active pendulum, thyssenkrupp Elevator’s development engineers can now test elevator systems under real conditions.

Great views into the future

The viewing platform is also taking shape with the glass balustrade now complete: Roughly four meter-high glass facades will ensure a 360° view from the test tower – looking out as far as the Alps in good weather conditions. It will also not be long until a further milestone in the construction phase of the tower is reached: Preparations for the installation of the membrane are nearly finished. A detailed survey of the tower is currently being conducted, and the installation platform for the membrane will be set up in July. Shortly afterwards, the test tower will be fitted with its spectacular exterior. The roughly 17,000 square meter-membrane made of polymer-coated fiberglass fabric will give the tower its final appearance. A highly complex material, it offers outstanding durability and is self-cleaning. The membrane not only gives the tower that certain je ne sais quoi, but also protects it from the effects of intense sunlight and helps reduce building sway by dispersing wind forces. The tower increases in transparency from the bottom to the top as the weave gradually becomes more wide-meshed. The polymer-coated fiberglass fabric is produced in sheets of approx. 3 meters, and are then welded together to form the large membrane panels.

This material was already used during the 2010 Soccer World Cup in Africa, where the “Cape Town Stadium” was covered in a translucent fiberglass membrane. This membrane also makes the extraordinary lighting concept of the test tower possible. Once complete, numerous LED lights behind the membrane will ensure that the tower is a true highlight.

“This structure is truly a beacon for thyssenkrupp,” said Schierenbeck. “We are still on course to begin trial operations in December 2016, and are currently planning the official inauguration ceremony and public opening of the visitor platform for May 2017.”

thyssenkrupp started building the test tower with the general contractor Züblin in 2014. Among the leading-edge technologies that will be tested in Rottweil is the newest-generation elevator, the MULTI. Three of the twelve shafts in the new test facility are reserved for the MULTI system which is powered by maglev technology from the Transrapid and provides a number of advantages: The cable-free design means several cabs can be operated in a single shaft. This increases passenger capacity per shaft by up to 50 percent and at the same time reduces the elevator footprint in a building by half. In addition, the elevators can move both sideways and vertically without height limitations, opening up completely new applications and architectural design possibilities.